Selecting the right valve for your system is more than just picking a part off a shelf; it’s a critical decision that impacts efficiency, safety, and long-term performance. Whether you are managing a large-scale industrial operation or a commercial plumbing project, the correct valve ensures that fluids move exactly as intended. This guide will walk you through the essential considerations for valve selection, from common types to critical performance factors.

Valves are designed for specific tasks. As such, understanding the basic types and their functions is the first step toward making an informed choice.

Ball valves are a popular choice for shutoff applications. They feature a rotating ball with a bore through the center. When the handle is turned, the bore aligns with the pipe for full flow or turns perpendicular to block it.

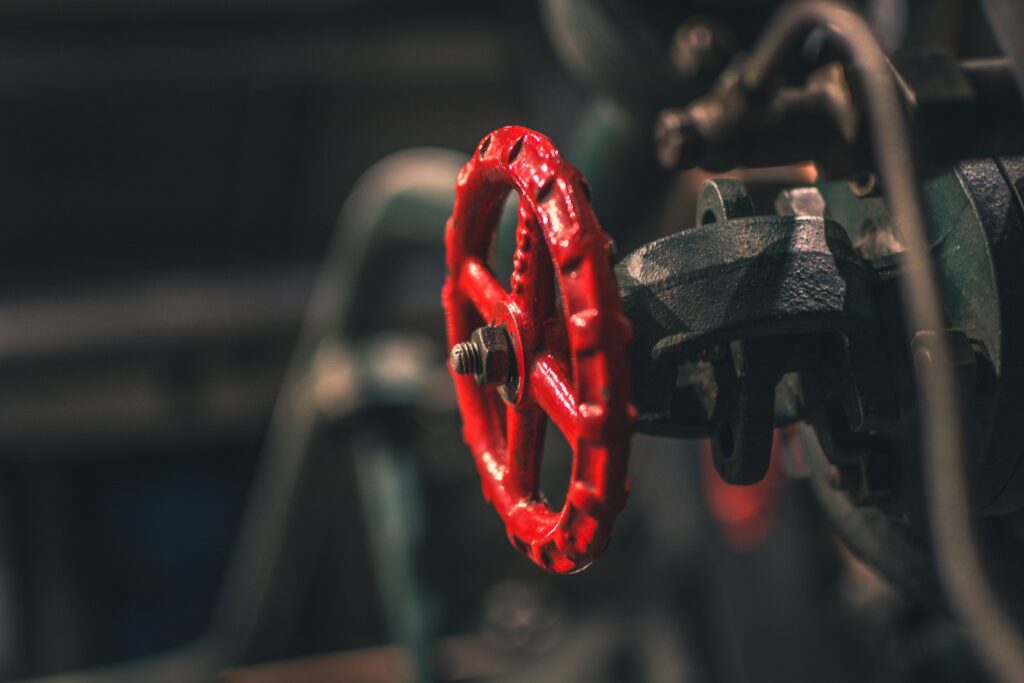

Gate valves utilize a flat gate that slides up and down to start or stop the flow of fluid. They are designed to be either fully open or fully closed. Because of this, they are not ideal for throttling or regulating flow.

Unlike gate valves, globe valves are excellent for throttling and regulating flow. They use a movable plug or disc that lowers onto a seat to control the flow rate. The fluid path is more complex, resulting in a higher pressure drop.

Butterfly valves are a reliable solution for controlling flow in a wide range of applications. Known for their simple quarter-turn operation, they are efficient, durable, and well-suited for both industrial and commercial use.

Check valves, or non-return valves, are designed to prevent backflow. However, unlike Butterfly Valves, they cannot be used to regulate flow. Check valves allow fluid to flow in one direction only. When the fluid tries to reverse, the valve automatically closes.

Choosing the right valve goes beyond its basic type. You must consider the specific conditions of your system to ensure optimal performance and safety.

Every valve has a maximum pressure it can safely withstand, defined by its pressure rating. You must select a valve with a rating that exceeds the maximum operating pressure of your system. Failing to do so can lead to leaks, equipment failure, and serious safety hazards. Consider both the operating pressure and any potential pressure surges.

The valve’s material must be compatible with the fluid passing through it. An incompatible material can corrode, erode, or contaminate the fluid, leading to valve failure and system-wide problems.

Consider what you need the valve to do. Do you need a simple on/off switch, or do you need to precisely regulate the flow rate?

To see how these principles work in practice, let’s look at a few examples:

A Commercial HVAC System: A building’s heating and cooling system requires precise temperature regulation. Globe valves are often used to throttle the flow of hot or chilled water to different zones, allowing for accurate climate control. Check valves are installed to prevent backflow in boiler and chiller loops, protecting expensive equipment.

An Industrial Chemical Plant: Handling corrosive chemicals requires robust and reliable valves. A plant might use stainless steel ball valves for quick shutoff on transfer lines. For controlling the flow of a reactant into a vessel, a specialized globe valve made of a corrosion-resistant alloy would be necessary to ensure both safety and process accuracy.

A Municipal Water Main: Large-diameter gate valves are installed within the city’s water distribution network. These valves remain open for years but can be closed to isolate sections of the pipeline for maintenance or emergency repairs, minimizing service disruption to residents.

Navigating the world of valves can be complex, but you don’t have to do it alone. At Detroit Nipple Works, we offer a diverse inventory of high-quality valves for any application. More importantly, our knowledgeable sales staff has the expertise to understand the unique demands of your project. We can help you analyze your system’s pressure, temperature, fluid type, and flow requirements to identify the perfect valve.

Don’t leave system performance to chance. Investing in the right valve from the start saves you time, money, and headaches down the road.

Need help choosing the right valve for your job? Contact us or call us at 1-888-698-7888 to speak to a Detroit Nipple Works specialist today!

Posted In: Ball Valves, Butterfly Valves, Gate Valves, Globe Valves, Valves

Tags: backflow check valves, ball valves Michigan, butterfly valves Michigan, gate valves Michigan, globe valves Michigan, Valve Selection