Threaded pipes play a crucial role in industries that rely on secure, efficient connections for flow systems. Among the many types of threads, ANPT and NPT are widely used for specific applications. However, unless you’re an engineer, these acronyms can be confusing. This guide breaks down the key differences and similarities between ANPT and NPT threads, making it easier to understand their unique applications.

Before we get into the specifics, it’s essential to understand what threading is. Threading refers to the screw-like grooves or lines cut into the ends of pipes, enabling them to attach securely to fixtures or other pipes. The primary purpose of threading is to create a tight seal between fittings, ensuring efficient assembly and preventing leaks. Different types of threading are designed to accommodate the specific needs of various industries.

Now, let’s focus on ANPT (Aeronautical National Pipe Taper) and NPT (National Pipe Taper) threads—two significant players in the world of threaded pipes.

NPT threads are a widely recognized standard for threaded pipes, especially in the United States. Standing for National Pipe Taper, these male and female pipe threads are tapered, meaning they are slightly conical. This design is intentional, as the tightening of the male and female parts compresses the threads, forming a reliable seal.

Tapered Design

The taper ensures that the threads wedge tightly together when torqued. This compression prevents leaks, making NPT pipes suitable for transporting gases and liquids safely.

Imperfect Threads

NPT pipes have a section of “imperfect threads” at the ends. These threads don’t engage fully but play a key role in achieving the seal when the connections are tightened.

Applications and Use

NPT threads are commonly used in plumbing, piping systems, and industrial applications where leak-proof seals are critical. However, repeated disassembly and reassembly of NPT connections may weaken their sealing capability over time.

NPT’s ability to create secure, leak-free joints makes it indispensable for applications involving potentially hazardous materials.

ANPT threads share some similarities with NPT but differ in key ways. ANPT stands for Aeronautical National Pipe Taper and, true to its name, is primarily used in aeronautical and military-grade applications. These threads are designed to meet stricter specifications for durability and precision.

Enhanced Regulation

ANPT thread dimensions—including taper, diameter, and thread form—are tightly controlled to ensure consistent performance. This strict regulation minimizes the chances of flaws or performance failures.

Military and Aeronautical Use

ANPT threads are specifically crafted for the demanding requirements of aviation and military applications. These pipes need to endure high stress, pressure, and environmental extremes.

Sealing Precision

Like NPT, ANPT threads rely on a tapered design to create seals. However, the precision involved in crafting ANPT threads ensures that they maintain their sealing integrity even under conditions of high vibration or other challenging factors.

While the taper and general form of ANPT threads mirror those of NPT, their strict adherence to precision and regulation differentiates them.

When deciding between ANPT and NPT threads, understanding your application is critical. For general industrial or domestic piping systems, NPT threads are often the go-to choice. However, if you’re working in an environment that demands high precision and durability, such as aviation or defense, ANPT threads are essential.

As you can see, NPT and ANPT have differences that make them useful in different industries. For more information, contact Detroit Nipple Works!

Rev: 7/25/2025

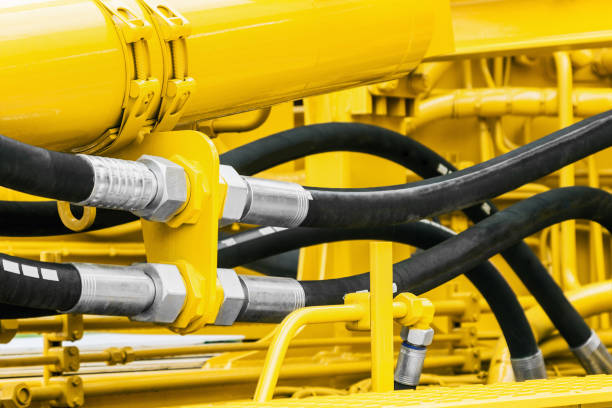

Hydraulic pipe provides transportation for fluid from one component to another. The three main liquids that will pass through a hydraulic pipe include petroleum oil, synthetic oil, and liquid with a high water content. Also, it is a very important part of the hydraulic system. The hose has to be able to tightly bend around all corners. Hose pipe flexibility enables components to be positioned inside the most efficient places, including tight places and across long distances.

Hydraulic pipe provides transportation for fluid from one component to another. The three main liquids that will pass through a hydraulic pipe include petroleum oil, synthetic oil, and liquid with a high water content. Also, it is a very important part of the hydraulic system. The hose has to be able to tightly bend around all corners. Hose pipe flexibility enables components to be positioned inside the most efficient places, including tight places and across long distances.

Hydraulic piping has many uses, the most general being to transfer liquids. In addition, the pipes can be used to transfer energy-generating liquid to different systems to function as a full hydraulic system. For these instances, the pipes and tubes have to be rigid and immobile so the system can be easily controlled. Also, in contrast, construction machinery usually has flexible and open hydraulic tubing so as to allow flexibility and free range of motion.

The type of hydraulic tube depends on its use and the pressures or chemicals it may be subjected to.

Knowing the correct threading of the hydraulic hose is important for repair. Selecting the wrong part can result in damage to the thread during installation. In addition, this negatively affects the pressure holding capacity and seal reliability of the hydraulic fitting. Also, there are six types of threads commonly used on hydraulic tube fittings:

Finally, for more information on hydraulic pipes and threading, contact Detroit Nipple Works today for a free quote!